The sizeable stable block at Farthing obviously needs a regular supply of feed and bedding, so two provender wagons have been made. I began with a diagram Q1, using the Coopercraft kit.

The GWR only made a total of 12 dedicated provender wagons, in two slightly different lots of six. The Q1 kit represents the later batch, built in 1903 with diagonal bracing. They were very camera shy, the (cropped) image above is the only one I have seen so far.

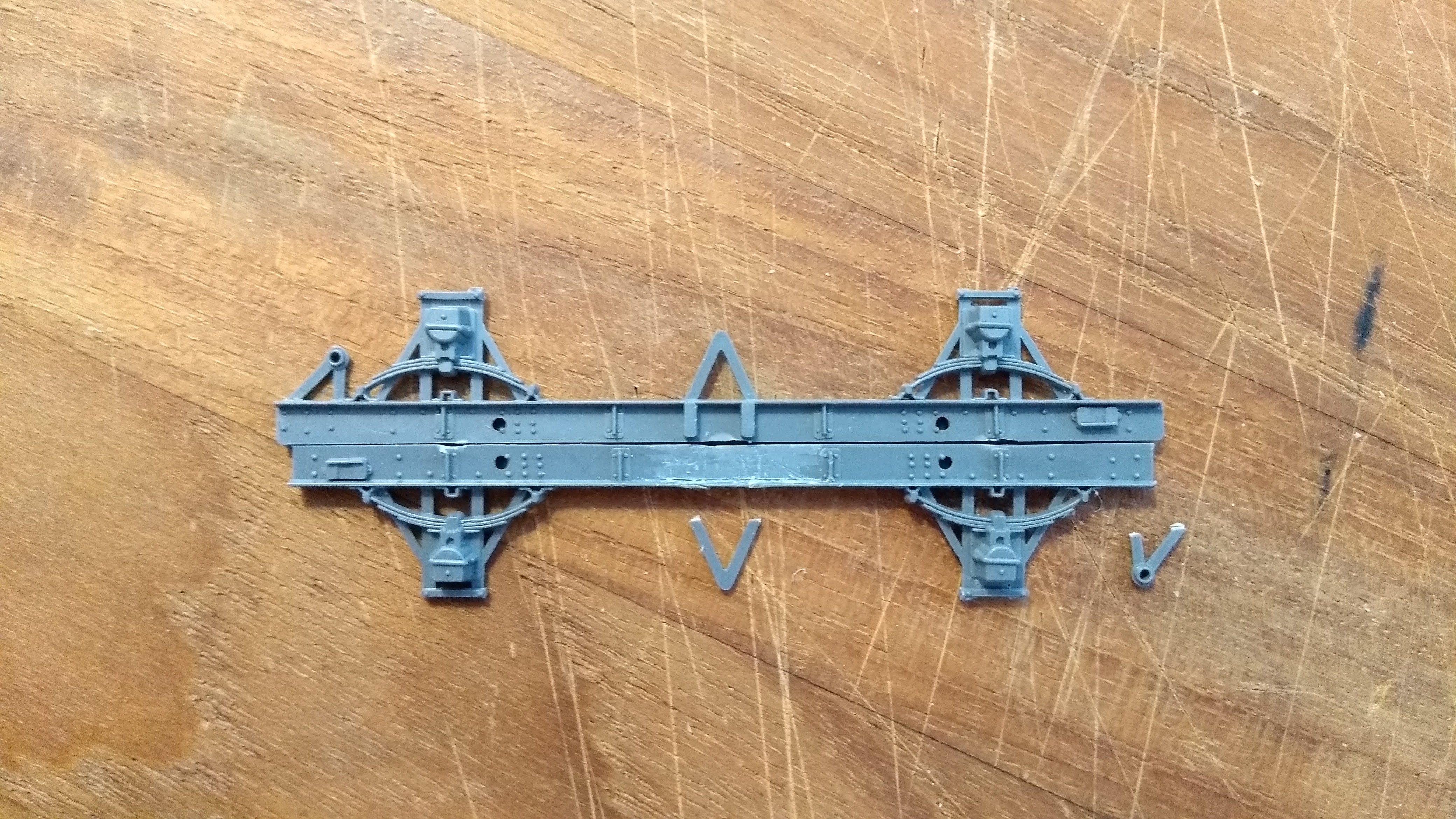

As usual, the build involved modifications. The Vee hanger on these wagons was significantly off-center, towards the right. The instructions don’t mention this. So both vees were cut off. The solebars need shortening, and the end brackets must therefore also come off. Here is the original solebar (top), and a modified one (below).

Then, sides and ends. The locating pips for the floor were removed. They make the floor sit too low, and the solebars in turn end up beneath the headstocks.

As provided, the brake gear does not take the off-center Vee into account, as this trial fit shows.

So the brake gear was modified to suit. Looks a bit odd, but that's what the drawing and text in Atkins et al shows.

The DC1 brake gear was made using parts from the Bill Bedford etch (recently withdrawn). The buffers are from Lanarkshire Models.

The finished wagon in GWR red, as it would have been painted when built in 1903.

Apart from 12 purpose-built provender wagons, most of the GWR's provender was carried in numerous standard open wagons of all sorts. Photos show them loaded improbably high. I decided to have a go at replicating this.

Not the 9 o’clock news. I set to work on some plumber’s hemp, cut fine and built up in layers on a foamboard box, using diluted PVA.

Then sheets (a.k.a. tarps) were made, using my usual method. The sheets were printed on regular paper, then laminated with thin foil and varnished multiple times, before weathering. The result is a shell that can be easily shaped and supports it’s own weight (see this post).

I designed the load to fit my 4-plankers. My initial plan was to have the entire load and sheeting detachable, in line with my normal approach. In this shot, the tarp and load are separate, but magnets hold them together and allow easy removal.

However, with a high load like this I felt that the lack of roping looked odd. So I decided to see how it would feel to have permanent loads and sheets. I recruited one of my 4-plankers and added roping and side-cords, using painted sewing thread.

Indents were made in the sheeting by pressing the edge of a ruler into the paper/foil shell, in order to emulate the ropes pulling down the sheet.

This is what I ended up with. Don’t look to closely at how the cords are tied at the ends. Photos of provender trains don’t show clearly whether and how they were used in a situation like this.

Sometimes, the GWR used two sheets laid sideways instead, as illustrated in this cropped detail of a train of hay bales.

I decided to do the same on my high-sided Q1 wagon. Here is the usual foil shell, this time composed of two sheets.

For the roping and cords, I loosely followed the cropped image above. I also tried to fold the sheets at the ends as per that photo, but gave up: Try as I might, it just looked weird in 4mm scale. Another time maybe.

Here are a few photos of the wagons in action on the (unfinished) new layout. A Buffalo class arrives with the weekly delivery of provender. Conveniently, the stable block at Farthing happens to have a siding alongside.

Meanwhile, Betty is having a drink in preparation for the morning round. Proper care of railway horses was a serious matter, though hardly for ethical reasons. Horses were a company asset and an important part of operations, so obviously needed good maintenance.

A close-up, warts and all. The mind struggles to accept that the hay wasn't completely covered over. There is room for improvement with the roping and cords, several lessons learnt there.

I'd like to experiment more with the shaping of the sheets. Here I have made slight rounded indents along the bottom to avoid a straight line. Period photos show that, although sheets were pulled as taut as possible, there were still lots of wrinkles etc.

Despite these experiments, I’m still undecided about permanent loads and sheeting. To illustrate my doubt: It's the next day and the Buffalo class is back to pick up the provender wagons. But wait, what’s this? They are still full and sheeted! More thinking needed. It never ends! 😊