Recently Bill Davies has been raising the standards of 3D-printed GWR loco bodies. I’ve been working on one of his offerings, the GWR “Buffalo” 1076 Class Saddle Tank.

Bill made the body to fit a Bachmann 57xx/8750 chassis. The project is a bit different from his other offerings, as it also requires a new wheelset with outside cranks. One option is to use a modified Bachmann 08 wheelset, which is what I did.

The detail on the print is impressive, as is the smoothness.

The body has the three-course saddle tank that was fitted with S4 boilers on many of the class from ca. 1895 onwards. The chimney appears to be the medium height variety, suggesting late Edwardian and later. The bunker is a type 2A with plated coal rails.

The closest photo match I could find is No. 1581 in 1923 (image courtesy gwr.org.uk). This loco was fitted with S4 boiler and 3-course saddle tank in January 1900 and remained in that overall condition until withdrawal in July 1929, never receiving panniers. I don’t know exactly how it looked in my 1910-1914 period, but it can’t have been much different so I’m going with that.

I thought I’d start with a drop test. From an overhead cupboard, about 2 meters. The silly thing broke. Bah humbug, useless new-fangled technology!

I’m joking of course. I did drop it but was impressed that the damage wasn’t worse. The major breakages were soon fixed with superglue as seen here.

On with the proper work. I addressed the chassis first, using a spare Bachmann 8750 from my stash. The older split chassis type won’t fit, it has to be one of the newer ones.

The backhead was removed, then the keeper-plate and wheelset.

The 57xx/8750 coupling rods are needed for the replacement wheelset. They are fitted with hexagonal threaded crankpins. I used Bachmann’s own "crankpin box spanner" to unscrew them.

Coupling rods ready for use. The 57xx/8750 wheelset and crankpins went in the spares box.

I then set to work on the 08 wheelset, acquired from the Bachmann Spares website. There are several variants available, in principle only the colours are different (but see below). This one is ref E3210-203-06. According to my calipers, the 08 wheels are 17.9 mms dia whereas the 57xx/8750 wheels are 18.61 mms. I can live with that.

The coupling rods were cut.

Then came the tricky bit: Removing the crankpins from the 08 wheels without damaging the cranks. The crankpins have a lip at the back. I filed this down carefully.

And was then able - with some difficulty - to pull out the crankpins using pliers.

This worked on all the wheels from the ref E3210-203-06 wheelset. I did have trouble with another 08 wheelset (for another project) which happened to have a different reference no. (E3210-203-19). Here the crankpins wouldn't budge and eventually a crank broke. Perhaps there are slight differences from batch to batch (material shrinkage or similar).

The 08 wheelset was then fitted with the 57xx rods. Bill is still working out what to do in terms of crank pins. I decided to simply refit the 08 crank pins. I filed them a little at the ends and was then able to push-fit them back in (different colours as one came off thatt other wheelset).

The modified wheelset under the 57xx chassis. Using the 08 crank pins is a bit of a bodge but works surprisingly well so far, including over points. It also worked for Tony who is doing the same conversion.

The chassis needed some further modification for the body to fit. The front end was cut back and the sand boxes cut through to clear the chassis. Later I patched it all up with bits of styrene.

A test run showed that the rear wheels touched the splashers. Filing away material is difficult as access is limited and the splashers are thin. Instead I packed strips of styrene in the two recesses under the bunker (ending with 0,75 mms and a longer fixing screw). This lifted the body clear of the rear wheels.

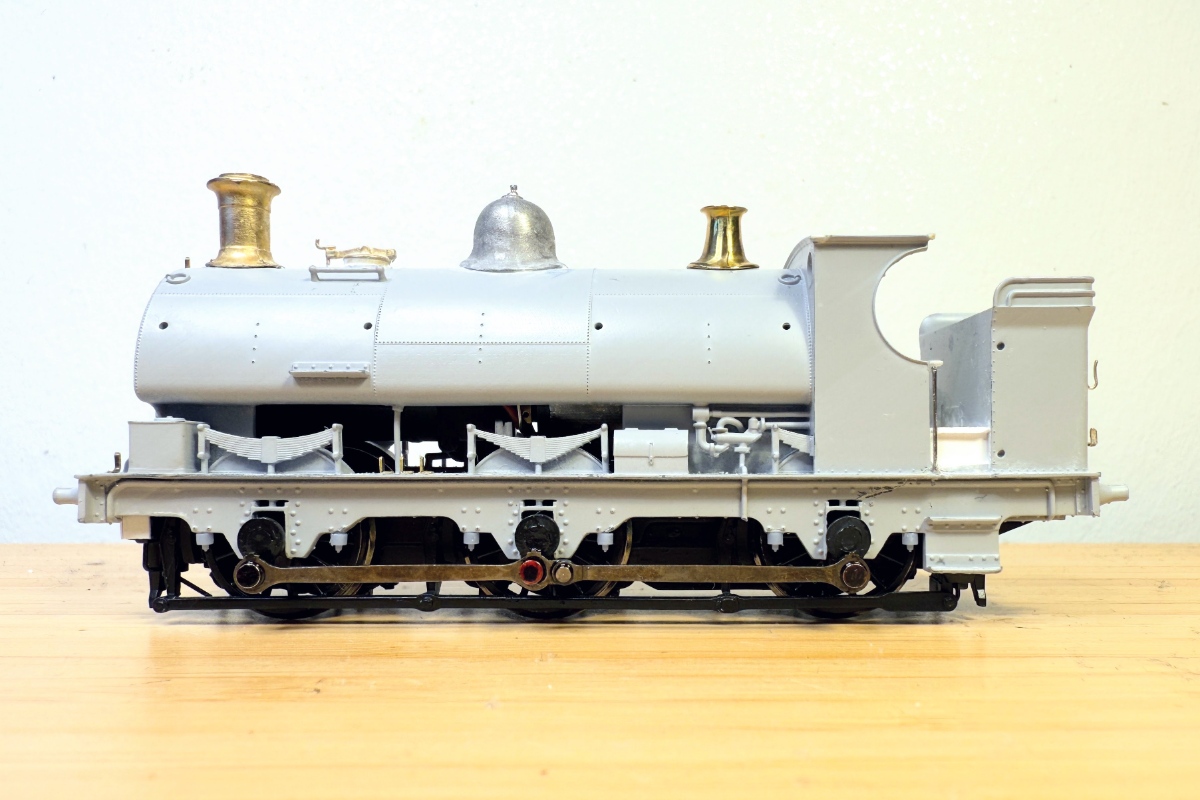

Body in place on the modified chassis.

I then attacked the boiler fittings. To my eyes the printed dome looks rather slim and upright for a saddle tank, and the chimney lacks a bit of profile. This work was done outside as I’m still not sure how toxic the dust is.

The tank filler also came off, as did the safety valve cover – the latter mostly as I had a nice polished brass one. Those wavy lines in the tank top are not scars but print artefacts with no actual contour.

New fittings from the spares box. I went for an Alan Gibson medium chimney and tank filler, an SEF or Nu-Cast dome (not sure) and a Martin Finney safety valve cover.

Before and after. The dome will be painted over but not the safety valve, a nod to the simplified but sometimes inconsistent livery on tank engines in the years before WW1.

Door darts from Brassmasters. Oryx from Schleich.

The cab interior needed work. The print features interior splashers and springs but is otherwise left bare, with the motor protruding into the cab – a necessary compromise with the 57xx chassis.

The photo of No. 1581 shows the floor raised above the splashers. By contrast the print has quite a low floor. So I built up a higher floor.

A rough backhead was fashioned from bits of scrap styrene, along with a raised floor section to cover the gears.

Backhead in place. Later some gauges were fitted. From past projects I know that, once the crew are installed, that step by the backhead isn’t really noticeable.

I was out of GWR lamp iron etches, so bent them up from cut back coach door handles (as a flat L-shape is needed for the fold). Not ideal, but sourcing parts from the UK is becoming a challenge, so tinkering is sometimes necessary.

Fire iron hooks fashioned from wire. Always a puzzle to get the relative positions of hooks and lamp irons reasonably right. As you can see, I made several attempts!

The danger of assumptions. Having made a couple of 1854s, I instinctively put the front side lamp irons on the sandboxes. Then discovered that Buffalos tended to have them on the running plate (regardless of period, it would seem).

So they were repositioned. Photos show them sometimes facing right, sometimes left.

The body comes with nicely printed springs. Twice as many as needed. Nice touch, no "ping" stress.

The springs fit into readymade holes. They required a bit of shortening

So that’s where I’m at. I now need to source some more handrail knobs and other small details, and then only the paintjob awaits.

Old and new. The original plan was to replace my ageing second-hand Buffalo, an M&L whitemetal kit. It has various inconsistencies and is a bit tall. But I don’t have the heart to retire it, and there’s room for both.

In the meantime I was pleased to find that a 3D printed loco body still leaves scope for some modelling. A good thing, I think.